Our Products

Book Free On-Site Advice from SRMB TMT Bar Experts

Get a free site visit from SRMB Steel and TMT Bar experts. Receive personalised solutions and expert guidance to select the best quality TMT bars in India for your project. Build smart and strong with SRMB, trusted for strength, durability, and long-term performance.

Request Your Site Visit Fill the form to schedule your free site visit

Why Choose SRMB

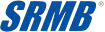

Superior Bond Strength with Concrete

1st company to introduce India's innovative ,patented designed ribs under the name of Wingrip Technology for better bonding of TMT bars with Concrete

Earthquake Resistance

Offers Superior Elongation

Green Steel

Manufacturing from the plant with Zero efficient discharge

Low Alloy Steel

Contains Low Carbon (Maximum 0.15%) in steel

Corrosion Resistance

Helps preserve and enhance the life of the structure

NABL Accredited Laboratory

One of the Few Steel manufacturers with in-house NABL accredited Laboratory

Longevity of Structure & Tensile Strength

Helps save about 17% Steel compared to normal TMT Fe415

Fire Resistance

Fire Resistance Fire Resistance

Become A Part Of Our Network Let's Build a Strong Foundation for the Nation

Our Iconic Projects

Major Business Partners

Major Consultants

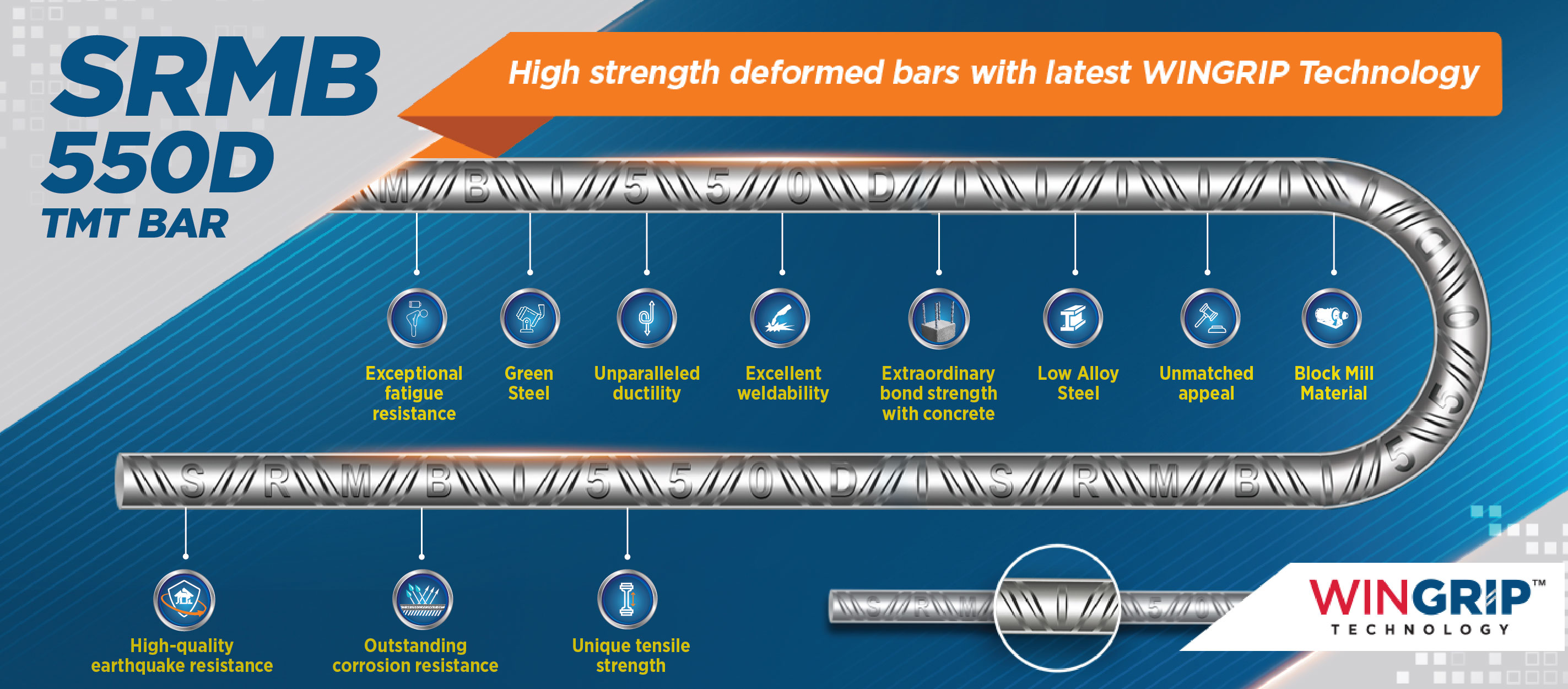

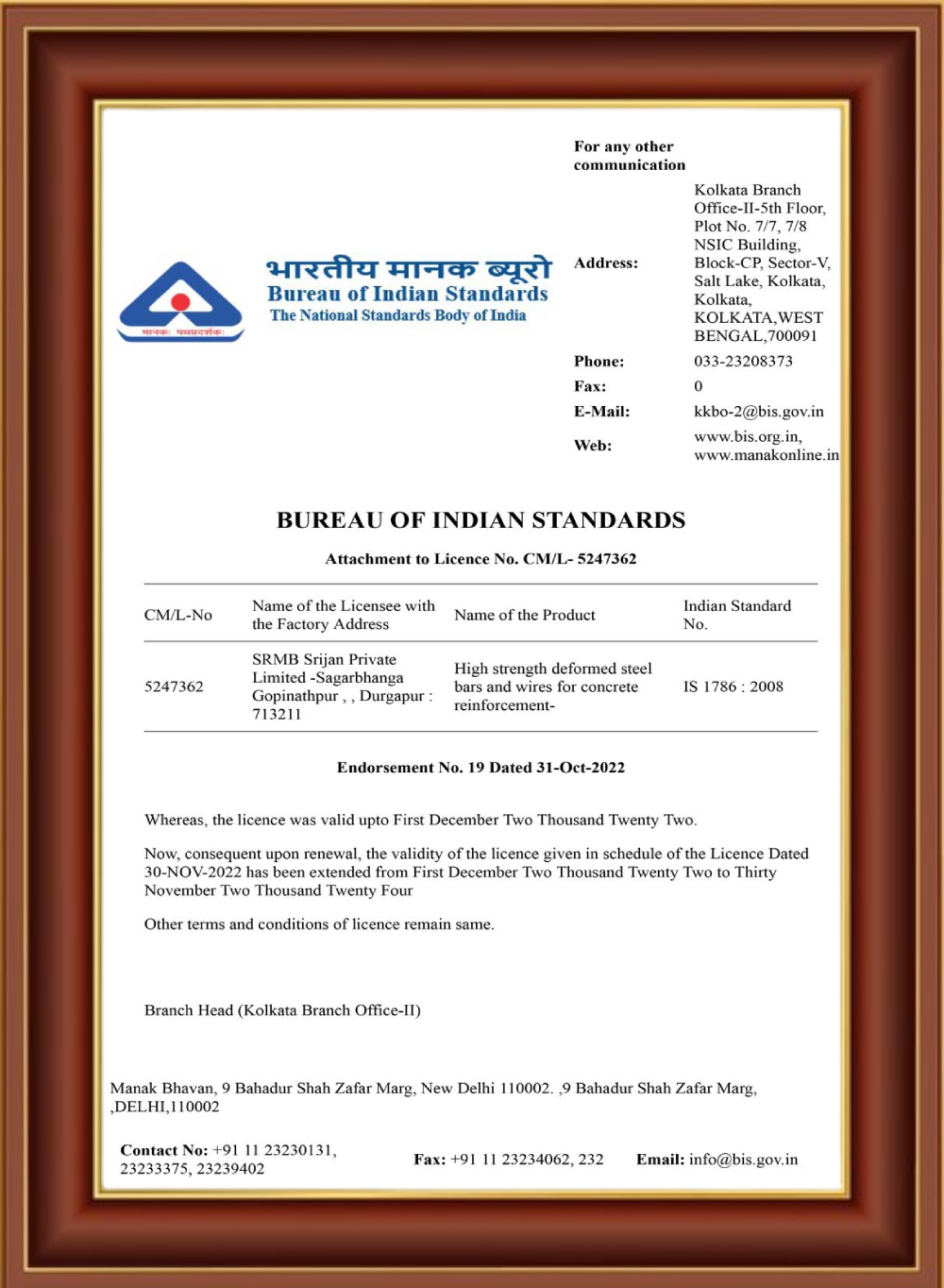

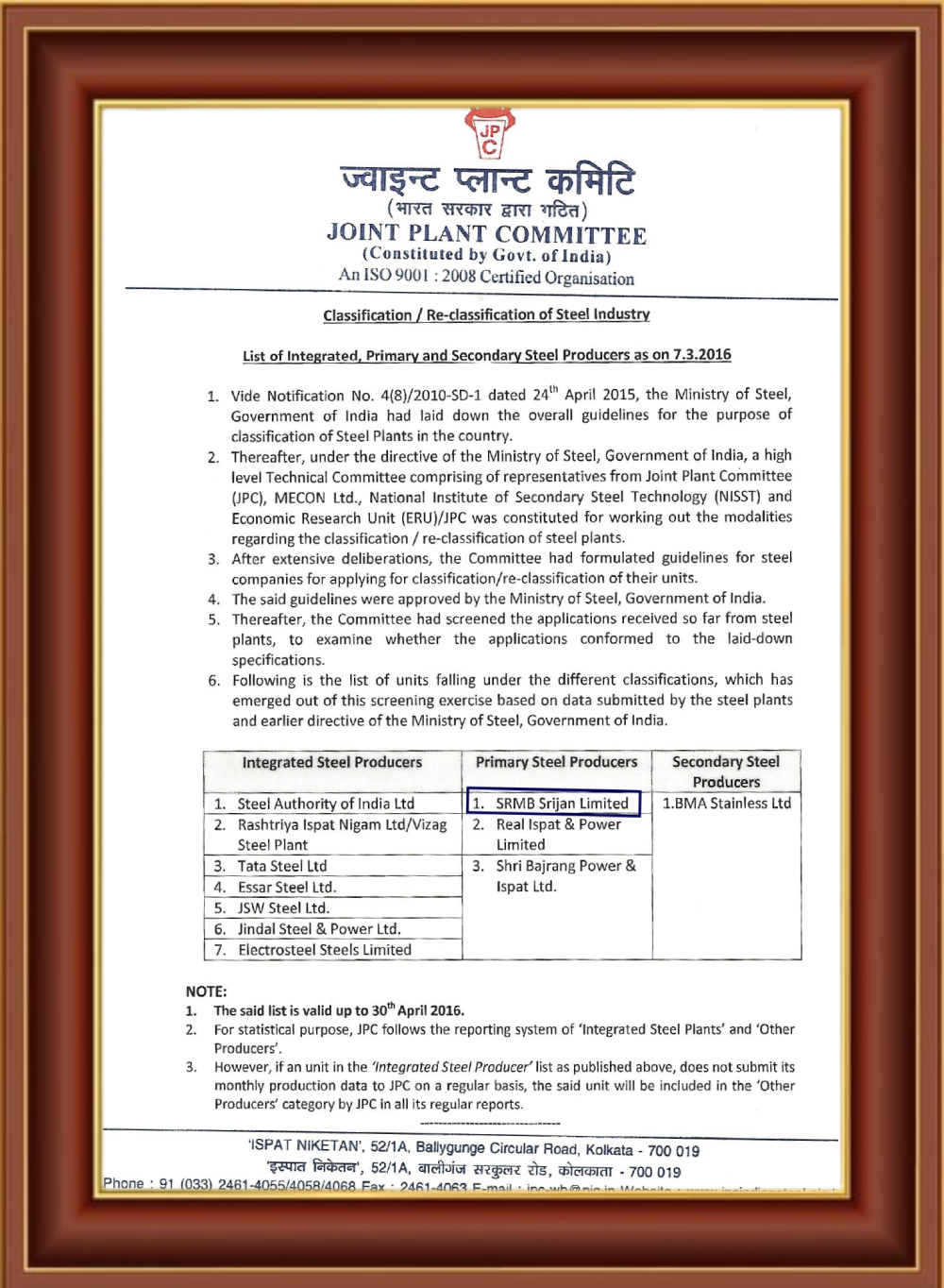

Certifications

Awards

Build Strong & Safe with the Best TMT Bar in India

We, at SRMB Steel, are proud to be among India's most reliable names in the construction industry. Having over seven decades of experience, we are still raising the standards in strength, durability, and innovation. Our best-selling product, the SRMB TMT Bar, is designed using the latest Wingrip technology, making it a builder's, engineer's, and consumer's first choice.

When you opt for SRMB, you are not only purchasing steel but investing in safety, reliability, and durability. Acknowledged as one of the best quality TMT bars in India, our offerings provide superior concrete bonding, improved earthquake resistance, and optimum cost-effectiveness. Whether constructing your dream house or developing mega infrastructure projects, SRMB is the finest TMT (saria) bar in India, relied upon by millions of people in the country.

Establish your future on a solid ground of trust and select SRMB Steel, where tradition meets innovation.