7 Things to Know About Your Construction TMT Bars

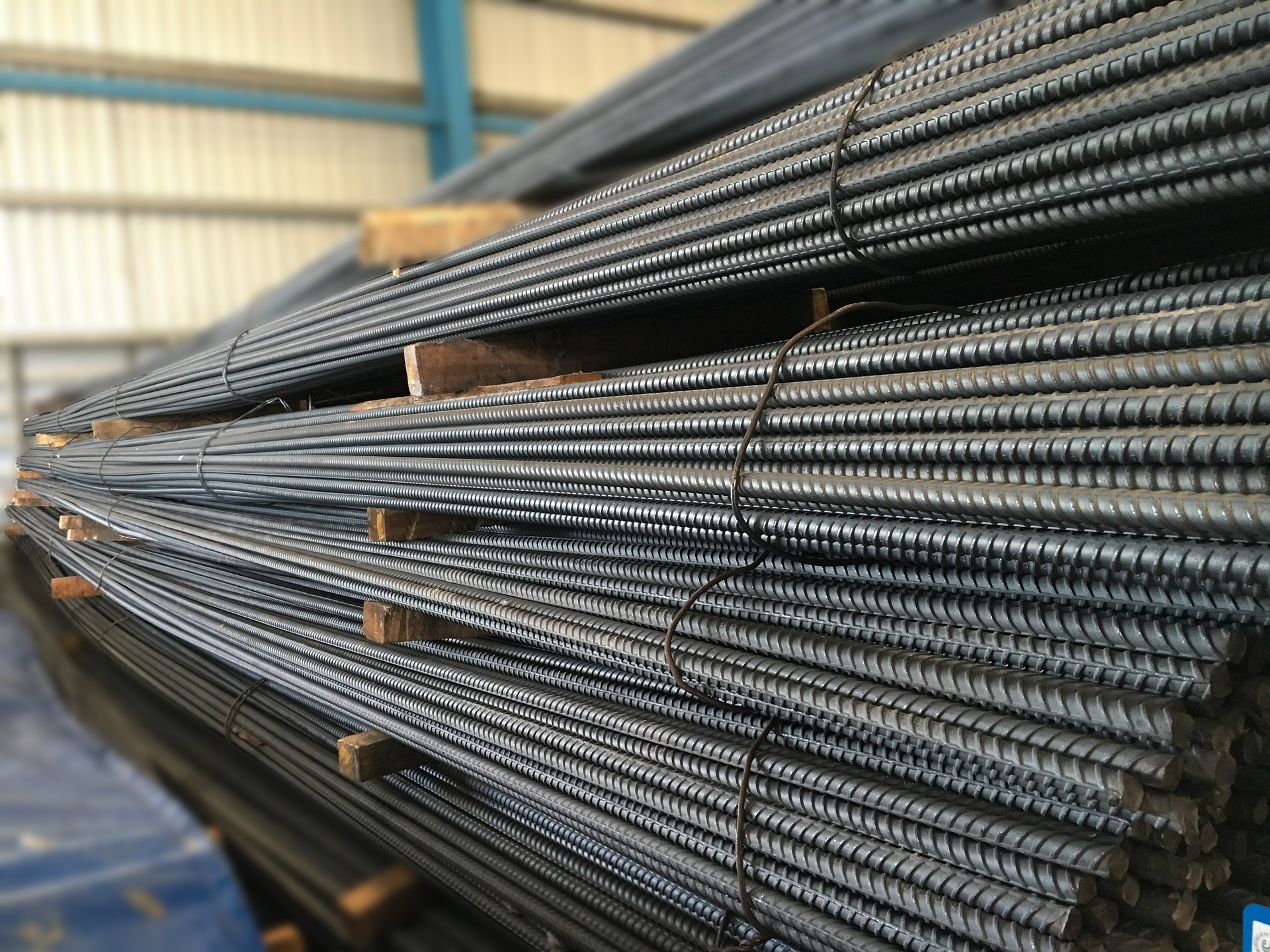

TMT bars make for the utmost important construction material.

You cannot go wrong while assessing the quality of the TMT bars for the construction of your dream house.

Here are 7 things you need to check before buying your TMT bar:

- Corrosion Resistant

Make sure you only buy the best of the quality of TMT bars available in the market.

TMT bars are made corrosion-resistant to dust off the rust thus, not allowing the building to tumble with the passing of years.

RELATED:

- Manufacturing process

The TMT Bars are produced from a new Tempcore Quenching Technology which hardens the outer surface leaving the inner core soft.

The process gives flexibility and ductility to the TMT bars.

- Grade of TMT bars

There’s a huge variety of Grades of TMT bars that cater to different constructional requirements.

These grades include:

- Grade Fe – 415

- Grade Fe – 415D

- Grade Fe – 500

- Grade Fe – 500D

- Grade Fe – 550

- Grade Fe – 550D

- Grade Fe – 600

- Earthquake-Resistant

If you’re situated in an earthquake prone zone, it is all the more important for you to assess the strength and flexibility of the TMT bars.

Earthquake-resistant TMT bars handle the sudden tectonic shocks and due to their superior flexibility, swaying from the earthquake renders minimal damage on the structure as a whole.

- Bonding Ability

TMT bars of good quality bond with the other construction materials like concrete easily, and without the interference of corrosion due to the formation of chloride ions.

They are wind-, water- & fire-proof with melting points as high as 400-600 degree Celsius.